Office Hours: Mon - Sat 8.00 - 18.00

Indirect Evaporative Cooling Unit

In tropical countries like India, summer cooling alone accounts for more than 60% of the annual electrical bill in air conditioned buildings. One of the most practical ways to increase a company’s bottom practice sustainability line is in addressing the energy use for air conditioning these buildings.

Since energy saving opportunity in conventional HVAC have been fractional, what is required is finding new smarter, simpler and energy efficient cooling solution. Indirect - Direct Evaporative Cooling (IDEC) is, a cost effective and sustainable modern technique for sensible cooling. With wider acceptance and use, this technology can help companies save substantially on their operating costs.

Applications

Special Features

- Energy Efficient :- Significant energy savings when compared with conventional HVAC

- Lowest Connected Loads :- Less than 30% energy usage as compare to conventional HVAC as IDEC systems uses only fans and low wattage pumps to produce cooling.

- CFC- free cooling:- IDFC systems use R718 as refrigerant which is natural thus have almost Zero GHG potential and a true sustainable method of cooling.

- Water savings:- Use 40% less water to provide most acceptable cooling when compared with conventional Evaporative cooling

- Competitive Life cycle cost:- Lowers operational cost, decrease power back up sizing, and minimal maintenance costs leads to real long-term savings at virtually little additional initial cost.

- Taper Wedges are used for fixing and locking of the insulated panels with aluminium frame

INDIRECT DIRECT EVAPORATING COOLING (IDEC) systems

In tropical countries like India, summer cooling alone accounts for more than 60% of the annual electrical bill in air-conditioned buildings. Since energy saving opportunity in conventional HVAC have been fractional, what is required is finding new smarter, simpler and energy efficient cooling solution. Indirect - Direct Evaporative Cooling (IDEC) is, a cost effective and sustainable modern technique for sensible cooling. With wider acceptance and use, this technology can help companies save substantially on their operating costs.

How the IDEC systems work?

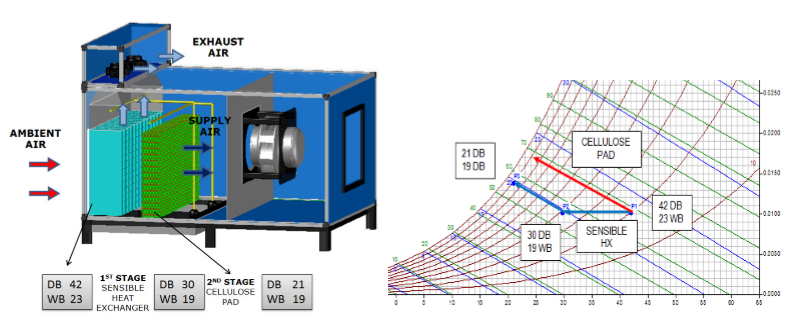

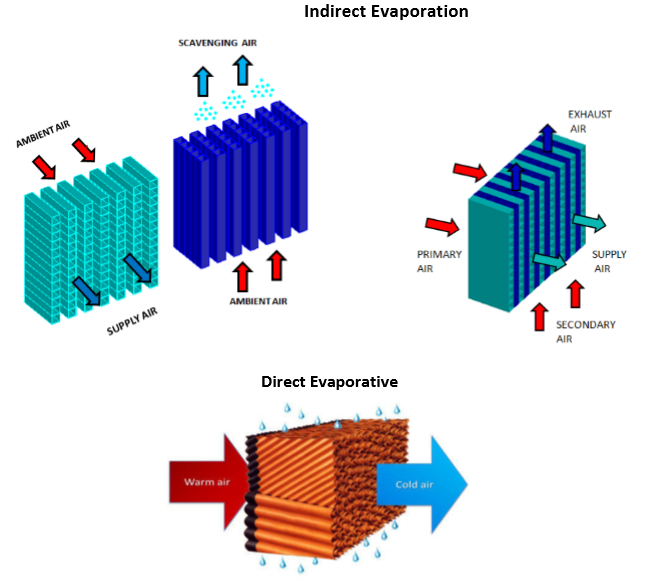

IDEC is two stage process which includes Indirect and Direct evaporation of water to cool supply air stream. . The first stage is Indirect Cooling stage where hot ambient air passes through sensible air to air cross flow heat exchanger where the sensible heat is removed. Heat exchanger is made up of engineered polymer having anti fungal, anti bacterial inert coating on wet side to improve the heat transfer through adjacent surfaces. Construction of heat exchanger is like a mesh of horizontal and vertical channels. In which ambient air enters from bottom and water is poured from top of vertical channel which forms uniform thin water film at inner surface and air is cooled by adiabatic evaporation in vertical channel. At the same time another air stream passes through the horizontal channel which is cooled by thermal conduction between air stream of horizontal and vertical channel. As water is not in direct contact with the horizontal air stream, the supply air is cooled by sensible cooling only without adding any moisture. Second stage is direct evaporation in which cellulose pads are used .when the cellulose pad get wetted, due to high surface area of heat transfer and uniform distribution of wet surface along the air stream evaporation efficiency is increased. In this stage cooling takes place through adiabatic evaporation and results in moisture addition in air stream. This air is now ready to pick up heat load from area to be cooled.

Advantages of TWO stage cooling

• Energy Efficient: Significant energy saving when compare to conventional HVAC

• Lowest Connected Loads: Less than 30 % energy usage as only fans and low wattage pumps required.

• Water saving: Use 30 % less water to provide require cooling with conventional evaporating cooling

• Competitive life cycle cost:Lower operational cost, decrease power back up sizing and minimal maintenance cost lead to real long term saving at little additional cost.

| Parameter | Units | TWO Stage IDEC | Evaporative Cooling System |

|---|---|---|---|

| location | City | Pune | Pune |

| Summer dry bulb | Dec C | 38 | 38 |

| Summer wet bulb | Dec C | 20.5 | 20.5 |

| Sensible heat load | TR | 25 | 25 |

| Supply air temp. | Dec C | 19 | 23 |

| Space temp. | Dec C | 28 | 28 |

| Air quantity | CFM | 17000 | 31000 |

| Absorb powder | KW | 8.5 | 19 |

| Water use | LPH | 325 | 420 |

| Economics | |||

| Operating time | HOURS/YEAR | 4000 | 4000 |

| Power tariff | INR/KHW | 8 | 8 |

| Installed Cost | INR lacs | 6.8 | 5 |

| Operating Cost | INR lacs | 2.88 | 6.4 |

Pre-cooled treated fresh air

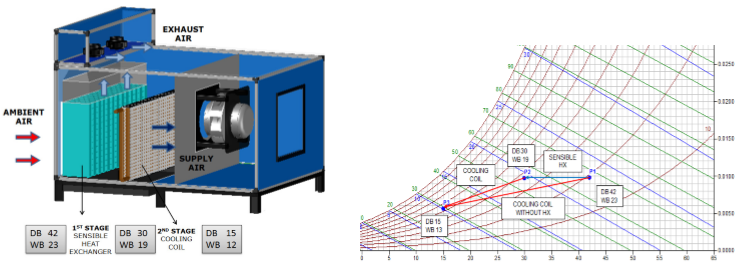

In conventional TFA only cooling coil is used but in pre-cooled TFA consist of two stages , first is indirect evaporation in which ambient air is sensibly cooled by air to air heat exchanger and then in second stage precooled air is passed through cooling coil to obtain the required air conditions. Due to precooling of air the heat load of coil is reduced through the reduction in Δ T on air side. Measurable energy and cost saving through overall HVAC circuit by reduction in required capacity of cooling coil and other components like condensing unit, piping and valve etc. The other advantage of TFA is, it offers unique heat recovery opportunity between incoming ambient air and building exhaust air without any cross contamination. Air to air heat exchanger can intake even toilet exhaust for heat recovery which is not possible with traditional heat recovery wheels.

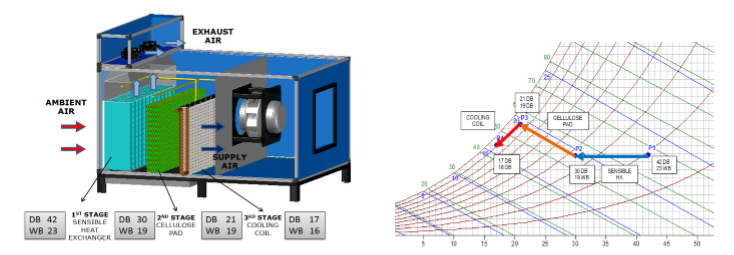

Three Stage Cooling

Three Stage cooling offers multiple operating modes to adjust efficiently with the fluctuating cooling demand throughout year. Three stage cooling consist of first Indirect cooling stage in which sensible cooling through Air to Air heat exchanger takes place . Second is direct evaporation stage in which adiabatic cooling takes place through wetted cellulose pad, while third stage is dehumidification with cooling with help of chilled water or DX cooling coil. First two stages cool the ambient fresh air at very low power penalty as 200 watts/TR during hot and dry season. which result in measurable energy saving due to reduction in cooling coil load. The advantage of three stage unit is, As per the required cooling load at site it can be operated in multiple combination of 1) heat exchanger + cellulose pad – this is used in dry ambient conditions like summer where only evaporation cooling can take care of heat load 2)heat exchanger + cooling coil – this is used as precooled TFA to reduced the load on coil where required RH to be controlled within particular limits 3) Only cooling coil – this is used in monsoon condition where evaporative cooling is not much efficient due to high humidity in ambient. By operating with suitable mode of cooling as per required cooling load three stage maximises the system efficiency with optimum operating cost.© Advantek2017 | Created with by Huphe